Since its establishment in 1992 in the picturesque state of Oregon, SakéOne has been at the forefront of the American craft saké movement. As the first craft saké brewery in the United States, we have dedicated ourselves to not only producing exceptional saké but also spreading the joy and appreciation of this beverage across the country. Join us as we take you on a captivating journey through the process of crafting saké, from rice to the glass.

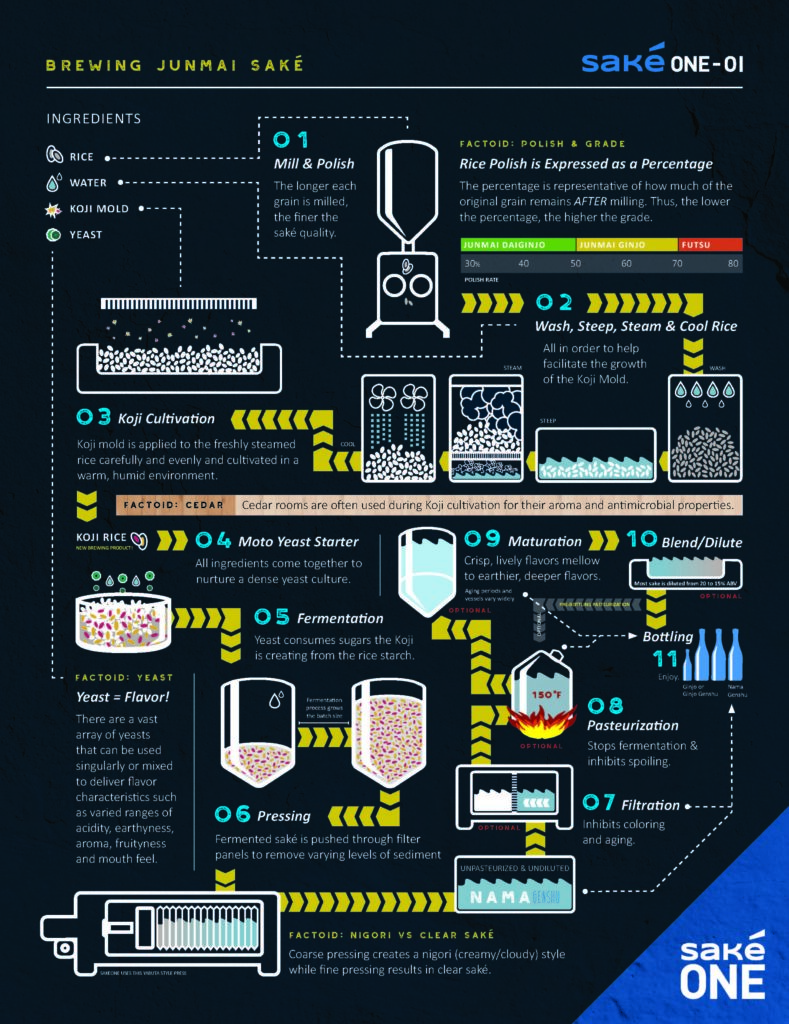

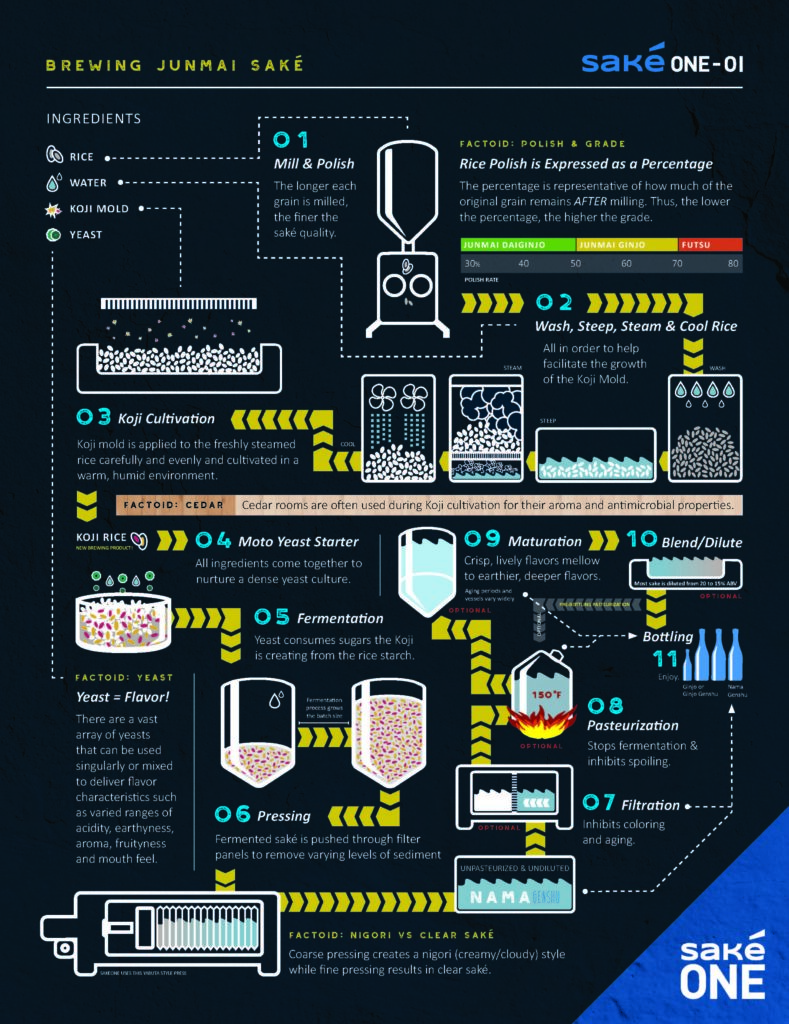

In the Kura, rice is milled and polished down to 58% of its original size. This polish rate is optimal for brewing Junmai Ginjo saké. For our exclusive Daiginjo saké, Naginata, the rice is polished down even further to an impressive 40%. During the milling process, the outer layers of rice are stripped away to reveal the starch-rich core, an essential element for saké production. The degree of milling greatly influences the ultimate quality, aroma, and flavor of saké.

Once the rice has been polished, it is time to cleanse it thoroughly. This step involves washing away any remaining rice powder, ensuring that the grains are clean. Following the washing process, the rice is steamed to achieve the ideal moisture content. After steaming, the rice is cooled down, preparing it for the next stage in the journey.

Koji, a mold called aspergillus oryzae, plays a pivotal role in the saké brewing process. It is sprinkled over the cooled rice, acting as a catalyst to convert the rice’s starches into fermentable sugars. This process, known as saccharification, is essential for the production of alcohol during fermentation.

To kickstart fermentation, a portion of the koji rice is mixed with water, steamed rice, and yeast. This mixture, known as the moto, ferments to develop the base for the main fermentation process. The moto is carefully nurtured to ensure a healthy and robust yeast population.

Now, the main fermentation process begins. The moto is combined with the remaining steamed rice, water, and yeast. Then, this mixture undergoes fermentation in temperature-controlled tanks. This step is critical as it determines the saké’s flavor profile and aroma.

Once fermentation is complete, the saké mash is gently pressed to separate the liquid from the solid sediment. The fermented saké is then carefully filtered through special panels, leaving behind any remaining sediment. After pressing and filtration, the saké is crisp and clear.

To stabilize the saké and preserve its flavor, it undergoes pasteurization. This process involves heating the saké to a specific temperature to stop any remaining fermentation and kill off any bacteria. Pasteurization ensures the saké retains its flavor and quality throughout storage and transportation.

After pasteurization, the saké is left to mature. The maturation period can vary, and during this time, the flavors harmonize, creating a balanced and refined taste profile.

The art of blending is the final touch in crafting the perfect saké. Our brewers blend batches of saké to achieve the desired flavor profile, ensuring consistency and excellence in every bottle.

Lastly, the finished saké is carefully bottled, sealed, and labeled, ready to be shared and enjoyed by customers across the nation.

At SakéOne, we take immense pride in every step of the saké brewing process. Our dedication to producing top-quality saké is matched only by our desire to educate and spread the love for this beverage. We welcome you to embark on a brewery tour, where you can witness firsthand the craftsmanship that goes into creating our saké. Kanpai!